BALLAST WATER TREATMENT System

SPARE PARTS

Compliance Solutions

BWTS Spare Parts

Ensure your BWTS meets regulations with original spare parts for reliable performance.Custom solutions help reduce the risk of invasive species in ballast water.Keeper helps with installation and ensures your system works properly.We guarantee your system stays compliant with all required standards.

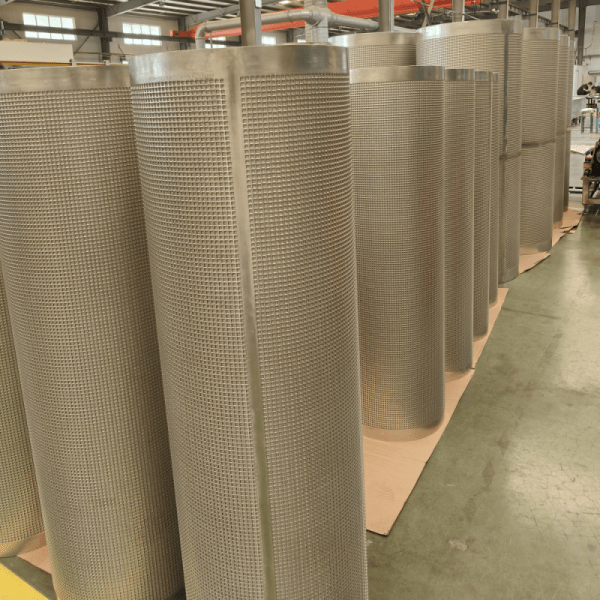

FILTER IN BWTS

Filter: Essential for BWTS, ensuring compliance, efficiency, and eco-friendliness in ballast water treatment.

TOTAL RESIDUAL OXIDANT (TRO) IN BWTS

BWTS includes TRO analysis for precise chlorine control, ensuring compliance and eco-friendly treatment.

HYDROGEN SENSOR IN BWTS

Ballast Water Treatment Systems (BWTS) uses Hydrogen Sensor XCD-STD for accurate hydrogen detection, ensuring safety and compliance in maritime operations.

CHLORINE SENSOR IN BWTS

BWTS employs a crucial Chlorine Sensor, ensuring precise chlorine measurement for safe and effective ballast water treatment, meeting rigorous industry standards.

PNEUMATIC PUMP IN BWTS

BWTS relies on the vital Pneumatic Pump for precise chlorine detection, ensuring compliance and safe marine operations.

Ballast Water Treatment Systems (BWTS) OVERVIEW

During ballasting, ballast water is filtered using an Automatic Back-Flushing Filter to remove large plankton and solid particles.

Next, in the disinfection phase, seawater passes through an Electrolytic Unit, which makes sodium hypochlorite. This is added back into the ballast pipe to kill marine organisms like plankton, pathogens, larvae, and spores.

When de-ballasting, a neutralizer is added to the treated water to remove any leftover oxidants (TRO). This ensures the water meets IMO D-2 and USCG VGP standards.

AUTOMATIC BACK-FLUSHING FILTER UNIT

Automatic back-flushing ballast filter with 50-micron screen removes plankton and particles, reducing oxidant use. Self-cleaning initiated at set pressure difference or time, discharging dirty water overboard.

AUTOMATIC NEUTRALIZATION UNIT

This unit neutralizes residual chlorite in de-ballasted water using Na2S2O3 solution. The by-products, NaCl and Na2SO4, pose no risks to receiving waters.

ELECTROLYTIC DISINFECTION UNIT

Electrolytic unit produces sodium hypochlorite from seawater for disinfection. Hydrogen by-product safely diluted. Seawater sourced from outlet, main pipe, or reserving tank during freshwater voyages.

MONITORING AND CONTROL SYSTEM

The monitoring and control system oversees the entire operation, it monitors and controls component statuses through local and remote control cabinets.