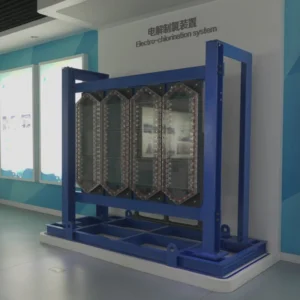

The Transparent Tubular Type Electro-Chlorination System from SUNRUI is designed to produce sodium hypochlorite by electrolyzing seawater or brine, offering an efficient and eco-friendly solution to marine biofouling.

Why Choose SUNRUI’s Transparent Tubular System?

- Transparent Design: The electrolyzer cell features a clear acrylic cover, allowing easy monitoring of the system’s condition. This design simplifies the cleaning process, ensuring optimal performance at all times.

- Eco-Friendly Solution: Unlike traditional liquid chlorine products, this system uses seawater to generate fresh sodium hypochlorite on-site. This reduces environmental pollution and minimizes risks to operators during handling and storage.

- Efficient and Cost-Effective: SUNRUI’s technology is more efficient, offering powerful chlorine sterilization without the high operational costs associated with other systems.

About SUNRUI

With over 30 years of experience, SUNRUI is a leading name in the electro-chlorination industry. The company has set national standards for electrolyzing seawater and has successfully exported its technology to more than 10 countries, including India, Malaysia, Indonesia, Turkey, UAE, the Philippines, and Laos.

Applications

SUNRUI’s Transparent Tubular Type Electro-Chlorination System is ideal for:

- Coastal power plants

- Marine and offshore platforms

- Industrial water treatment facilities

Typical Models and Performance

The system offers a wide range of models to suit different seawater conditions, producing varying amounts of chlorine (Cl2) and sodium hypochlorite concentrations. The transparent tubular design ensures easy supervision, making it a reliable choice for various industrial applications.

If you’re looking for an efficient, eco-friendly solution for marine biofouling control, SUNRUI’s Transparent Tubular Type Electro-Chlorination System is the ideal choice.

| Seawater Condition | Seawater Condition | Seawater Condition | Sodium Hypochlorite Concentration |

|||||

| Model | 5<T<10℃ TDS 30-36g/L |

10<T<15℃ TDS36-40g/L |

15<T<34℃ TDS38-48g/L |

ppm | ||||

| Minimum kg/h Cl2 |

Maximum kg/h Cl2 |

Minimum kg/h Cl2 |

Maximum kg/h Cl2 |

Minimum kg/h Cl2 |

Maximum kg/h Cl2 |

Minimum | Maximum | |

| 2-HE401 | 1 | 2 | 2 | 3 | 3 | 4 | 300 | 500 |

| 2-HE602 | 1 | 3 | 3 | 5 | 5 | 5 | 500 | 1000 |

| 2-HE603 | 4 | 8 | 10 | 13 | 14 | 16 | 500 | 1000 |

| 2-HE604 | 6 | 12 | 14 | 20 | 21 | 23 | 500 | 1000 |

| 3-HE604 | 9 | 18 | 21 | 30 | 32 | 35 | 500 | 1000 |

| 2-HE805 | 8 | 16 | 18 | 26 | 28 | 30 | 500 | 1000 |

| 3-HE805 | 12 | 24 | 28 | 39 | 41 | 45 | 500 | 1000 |

| 2-HX075 | 8 | 12 | 13 | 15 | 750 | 1500 | ||

| 2-HX150 | 16 | 24 | 27 | 30 | 750 | 1500 | ||

| 2-HX300 | 32 | 48 | 54 | 61 | 750 | 1500 | ||

| 2-HX400 | 44 | 67 | 75 | 85 | 750 | 1500 | ||

| 3-HX075 | 12 | 18 | 20 | 23 | 750 | 1500 | ||

| 3-HX150 | 24 | 36 | 40 | 46 | 1000 | 1800 | ||

| 3-HX300 | 48 | 71 | 81 | 91 | 1000 | 2000 | ||

| 3-HX400 | 67 | 100 | 113 | 128 | 1000 | 2000 | ||

| 2-VE805 | 76 | 86 | 1200 | 2000 | ||||

| 2-VEX05 | 95 | 108 | 1500 | 2000 | ||||

| 2-VE810 | 153 | 174 | 1200 | 2000 | ||||

| 2-VEX10 | 191 | 217 | 1500 | 2000 | ||||

| 3-VE805 | 114 | 129 | 1500 | 2000 | ||||

| 3-VEX05 | 143 | 162 | 1500 | 2000 | ||||

| 3-VE810 | 230 | 260 | 1500 | 2000 | ||||

| 3-VEX10 | 287 | 325 | 1500 | 2000 | ||||

| 4-VEX10 | 383 | 434 | 1500 | 2000 | ||||

Reviews

There are no reviews yet.