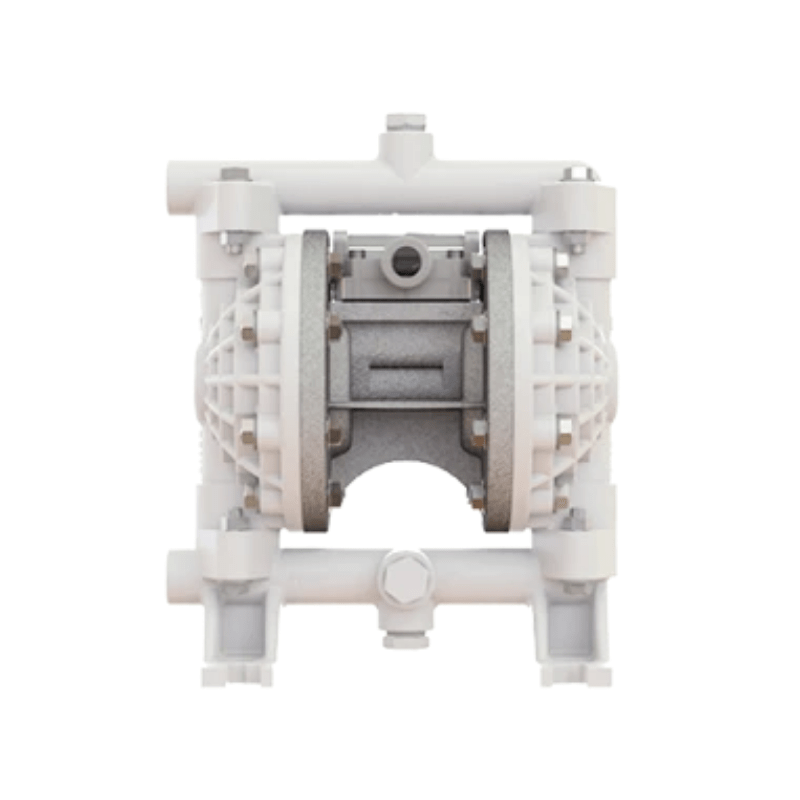

Product Name: Pneumatic Pump for SUNRUI BWMS VERSA-MATIC 1/2″ Bolt Non-Metallic Diaphragm Pump E5

Material Composition:

- Center Section: Aluminum, Polypropylene

- Wetted Parts: Conductive Acetal, Conductive Polypropylene, Polypropylene, PVDF

Performance Parameters:

- Flow Rate: 0-11 GPM (53 LPM)

- Size: 1/2″

- Suction Lift:

- Dry Suction: 12′ (3.6 m)

- Wet Suction: 30′ (9.1 m)

- Maximum Solid Particle Size: 1/16″ (1.6 mm)

- Weight:

- Polypropylene: 8.5 lbs (3.9 kg)

- PVDF: 12 lbs (5.4 kg)

Common Models:

- E5KP5F5T9

- E5KP5T5T9

- E5KP6X669

- E5PP2R229

- E5PP5F5T9

- E5PP5T5T9

- E5PP6X569

- E5PP6X669

- E5PP6X6T9

Product Features:

- Superior Materials: The center section is made of aluminum or polypropylene, while the wetted parts are made of high-performance materials such as conductive acetal, conductive polypropylene, polypropylene, and PVDF, offering excellent corrosion resistance and durability.

- Outstanding Suction Performance: The pump can achieve a dry suction lift of up to 12 feet (3.6 meters) and a wet suction lift of up to 30 feet (9.1 meters), meeting various operational needs.

- Efficient Flow Rate: With a flow range of 0-11 GPM (53 LPM), this pump is suitable for a wide range of industrial applications.

- Lightweight Design: The pump is lightweight, with the polypropylene model weighing only 8.5 lbs (3.9 kg) and the PVDF model weighing 12 lbs (5.4 kg), making it easy to install and operate.

- Multiple Model Options: A variety of models are available to meet different application requirements.

Instructions for Use:

- Installation: Install the pump on a stable and sturdy base, ensuring that all connections are properly sealed to prevent leaks.

- Connection: Select the appropriate pipe size and fittings according to your needs, and connect the pump correctly to the system.

- Operation: After starting the pump, check the flow rate and suction lift to ensure they meet the technical specifications.

- Maintenance: Regularly inspect the pump components to ensure proper operation. If any abnormalities are found, repair or replace the relevant parts promptly.

Precautions:

- Avoid Dry Running: Do not operate the pump without liquid, as this can cause damage.

- Prevent Blockages: Ensure that the liquid being pumped does not contain particles larger than the maximum solid particle size to avoid clogging.

- Storage Conditions: When not in use for extended periods, clean the interior of the pump and store it in a dry and well-ventilated place.

Reviews

There are no reviews yet.